I've updated the test code I'm using to manage my X and Y axis DC motor / linear encoder closed loop controller.

I am currently using the Arduino PID Library by Brett Beauregard for this, and having great success. Videos to come tomorrow.

I am *NOT* going to explain what PID is, or how PID works.... I couldn't possibly do it justice. I'll simply point you to Brett's wonderful explanation:

In the following example, I set up two axis, X and Y, each using a DC motor run from the Adafruit Motor Shield V2. This shield provides PWM control for up to four separate DC motors via I2C communications.

I then set up two Quadrature encoders, one for each axis, using the Hardware Interrupts 0 and 1 (Arduino digital pins 2 and 3) and high speed digital port reads for one half of each encoder, and then validate the state of the other phase pin of the encoder during the interrupt routine:

Graciously borrowed from http://forum.arduino.cc/index.php?topic=41615.20;wap2

The ZERO endstop for each axis is set up using the Arduino PinChangeInterrupt library watching a pin attached to a photo-interrupter.

Inside the loop portion of my code, I run the PID controls as per the library, providing motor speed control via the Adafruit motor class, and periodically check to see if both X and Y axis have reached their goal. At which time, I randomly select a new target for each. When I get to the real application of this, the random selection of X and Y axis targets will be replaced by GRBL coordinates.

I then set up two Quadrature encoders, one for each axis, using the Hardware Interrupts 0 and 1 (Arduino digital pins 2 and 3) and high speed digital port reads for one half of each encoder, and then validate the state of the other phase pin of the encoder during the interrupt routine:

Graciously borrowed from http://forum.arduino.cc/index.php?topic=41615.20;wap2

The ZERO endstop for each axis is set up using the Arduino PinChangeInterrupt library watching a pin attached to a photo-interrupter.

I would certainly accept any advice on a proper sequence to initialize each axis to the ZERO endstop.

Right now, I arbitrarily send the carriage forward for 100ms assuming this is enough time to get on the positive side of the endstop, if we were beyond it. Then I set my current position to the maximum possible location, and start travelling back to the endstop, knowing that once I actually reach it, the interrupt routine will Zero out my position, and initialize my PID setpoint to zero as well, thus stopping travel at ZERO.

Is there a more efficient way of doing this?

Inside the loop portion of my code, I run the PID controls as per the library, providing motor speed control via the Adafruit motor class, and periodically check to see if both X and Y axis have reached their goal. At which time, I randomly select a new target for each. When I get to the real application of this, the random selection of X and Y axis targets will be replaced by GRBL coordinates.

And without further ado, here is my working code for precise position control in X and Y axis using the Arduino PID library:

https://github.com/michaeljball/RepScrap/**************************************************************************************** Lin_Enc_02.ino 05-12-2014 unix_guru at hotmail.com @unix_guru on twitter* http://arduino-pi.blogspot.com** This sketch allows you to run two salvaged printer carriages for X/Y axis using their* linear encoder strips for tracking.* This example uses the Arduino PID Library found at:* https://github.com/br3ttb/Arduino-PID-Library/archive/master.zip** Hardware Interrupt 0 on Digital pin2 is used to determine X-Axis position* Hardware Interrupt 1 on Digital pin3 is used to determine Y-Axis position* PinchangeInterrupt is used to identify the Zero Endstop for X and Y axis*****************************************************************************************/#include <Wire.h>#include <Adafruit_MotorShield.h>#include "utility/Adafruit_PWMServoDriver.h"#include <PID_v1.h>#include <PinChangeInt.h>#define frontstop = 100 // Right most encoder boundary#define backstop = 3600 // Left most encoder boundary// Create the motor shield object with the default I2C addressAdafruit_MotorShield AFMS = Adafruit_MotorShield();// Select which 'port' M1, M2, M3 or M4. In this case, M1Adafruit_DCMotor *XaxisMotor = AFMS.getMotor(1);Adafruit_DCMotor *YaxisMotor = AFMS.getMotor(2);const int XaxisENCPinA = 2; // X-AXIS encoder 1 on pins 2 and 4const int XaxisENCPinB = 4;const int XaxisENDSTOP = 10; // Endstop photointerrupter for X-Axisvolatile double XaxisENCPos = 0;const int YaxisENCPinA = 3; // Y-AXIS encoder 2 on pins 3 and 5const int YaxisENCPinB = 5;const int YaxisENDSTOP = 11; // Endstop photointerrupter for Y-Axisvolatile double YaxisENCPos = 0;double XaxisSpd, YaxisSpd; // Carriage speed from 0-255double XaxisPos, YaxisPos; // Current Carriage position/*working variables for PID routines*/// Tuning parametersfloat KpX=0, KpY=0; //Initial Proportional Gainfloat KiX=10, KiY=10; //Initial Integral Gainfloat KdX=0, KdY=0; //Initial Differential Gaindouble XaxisSetpoint, YaxisSetpoint; // Taget position for carriage// Instantiate X and Y axis PID controlsPID XaxisPID(&XaxisPos, &XaxisSpd, &XaxisSetpoint, KpX, KiX, KdX, DIRECT);PID YaxisPID(&YaxisPos, &YaxisSpd, &YaxisSetpoint, KpY, KiY, KdY, DIRECT);const int sampleRate = 1;long int reportTime;void setup() {Serial.begin(115200);Serial.println("Linear Encoder Test 05-12-2014");AFMS.begin(); // Set up MotorsXaxisMotor->run(BACKWARD); // Bring carriage to home position.XaxisMotor->setSpeed(70);delay(100); // Get endstop limiter working hereXaxisMotor->run(FORWARD); // Bring carriage to home position.XaxisMotor->setSpeed(0);

YaxisMotor->run(BACKWARD); // Bring carriage to home position.YaxisMotor->setSpeed(70);delay(100); // Get endstop limiter working hereYaxisMotor->run(FORWARD); // Bring carriage to home position.YaxisMotor->setSpeed(0);attachInterrupt(0, doXaxisENC, CHANGE); // encoder pin on interrupt 0 (pin 2)attachInterrupt(1, doYaxisENC, CHANGE); // encoder pin on interrupt 1 (pin 3)PCintPort::attachInterrupt(XaxisENDSTOP,doXaxisEndstop,FALLING); //X-axis Endstop ISRPCintPort::attachInterrupt(YaxisENDSTOP,doYaxisEndstop,FALLING); //Y-axis Endstop ISRrandomSeed(analogRead(0)); // Used to select random setpoints for testingXaxisPID.SetMode(AUTOMATIC); //Turn on the PID loopXaxisPID.SetSampleTime(sampleRate); //Sets the sample rateYaxisPID.SetMode(AUTOMATIC); //Turn on the PID loopYaxisPID.SetSampleTime(sampleRate); //Sets the sample ratereportTime = millis()+2000;}void loop() {uint8_t oldSREG = SREG; // Store interrupt status registercli();XaxisPos = XaxisENCPos;YaxisPos = YaxisENCPos;SREG = oldSREG; // Restore interrupt status register// Temporary to create random X and Y axis setpoints for testingif(millis() > reportTime) { // Only validate this every 2 secondsif(XaxisPos == XaxisSetpoint && YaxisPos == YaxisSetpoint) {// If both X-axis and Y-axis have reached their target - get new targetsXaxisSetpoint = random(200,3500); // Keep target within bounds of EndpointsYaxisSetpoint = random(200,3500); // Keep target within bounds of Endpoints}reportTime = millis()+2000;}// Manage X-axis positioningXaxisPID.Compute(); //Run the PID loopif(XaxisSetpoint < XaxisPos) XaxisMotor->run(BACKWARD); // Determine direction of travelelse XaxisMotor->run(FORWARD);XaxisMotor->setSpeed(XaxisSpd); // Apply PID speed to motor// Manage Y-axis positioningYaxisPID.Compute(); //Run the PID loopif(YaxisSetpoint < YaxisPos) YaxisMotor->run(BACKWARD); // Determine direction of travelelse YaxisMotor->run(FORWARD);YaxisMotor->setSpeed(YaxisSpd); // Apply PID speed to motor}/***************************************************************************************The following code was taken from http://forum.arduino.cc/index.php?topic=41615.20;wap2to utilize the fast port based encoder logic. Thank you Lefty!please go there for a full explanation of how this works. I have truncated the commentshere for brevity.***************************************************************************************/void doXaxisENC() { // ************** X- AXIS ****************if (PIND & 0x04) { // test for a low-to-high interrupt on channel A,if ( !(PIND & 0x10)) { // check channel B for which way encoder turned,XaxisENCPos = ++XaxisENCPos; // CW rotation}else {XaxisENCPos = --XaxisENCPos; // CCW rotation}}else { // it was a high-to-low interrupt on channel Aif (PIND & 0x10) { // check channel B for which way encoder turned,XaxisENCPos = ++XaxisENCPos; // CW rotation}else {XaxisENCPos = --XaxisENCPos; // CCW rotation}}} // End of interrupt code for encoder #1void doYaxisENC(){ // ************** X- AXIS ****************if (PIND & 0x08) { // test for a low-to-high interrupt on channel A,if (!(PIND & 0x20)) { // check channel B for which way encoder turned,YaxisENCPos = ++YaxisENCPos; // CW rotation}else {YaxisENCPos = --YaxisENCPos; // CCW rotation}}else { // it was a high-to-low interrupt on channel Aif (PIND & 0x20) { // check channel B for which way encoder turned,YaxisENCPos = ++YaxisENCPos; // CW rotation}else {YaxisENCPos = --YaxisENCPos; // CCW rotation}}} // End of interrupt code for encoder #2void doXaxisEndstop() {XaxisENCPos=0; // X-Axis Endstop indicates ZERO position}void doYaxisEndstop() {YaxisENCPos=0; // Y-Axis Endstop indicates ZERO position}

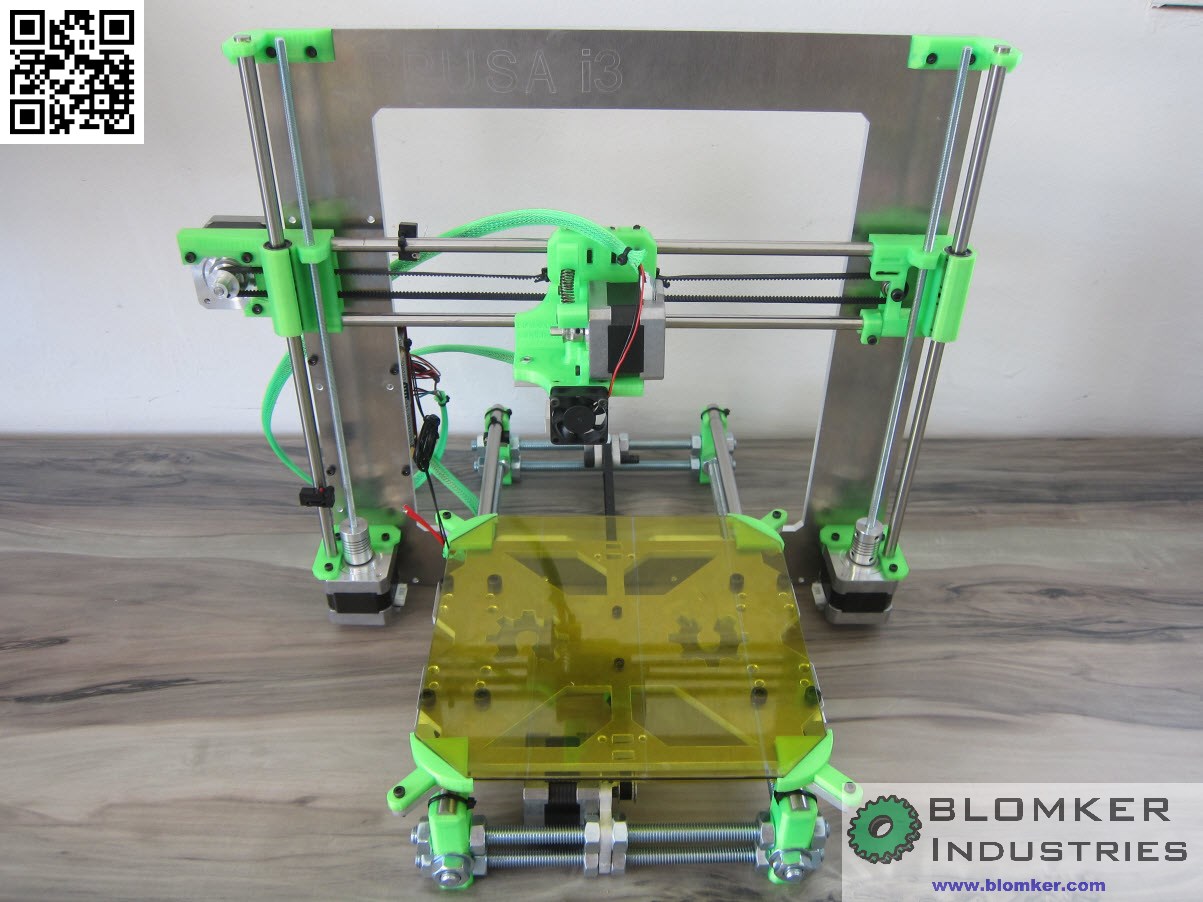

Updated diagram for reference:

References:

DIYDrones: Tutorial series for new Arduino PID library

http://brettbeauregard.com/blog/2011/04/improving-the-beginners-pid-introduction/

http://robotics.stackexchange.com/questions/1232/how-can-i-use-the-arduino-pid-library-to-drive-a-robot-in-a-straight-line

Tim Wescott's PID without a PHD

http://abigmagnet.blogspot.ca/2008/10/dc-motor-control-part-one.html

http://www.pdx.edu/nanogroup/sites/www.pdx.edu.nanogroup/files/2013_Arduino%20PID%20Lab_0.pdf

https://www.youtube.com/watch?v=ZZYgZjMnGXU

https://www.youtube.com/watch?v=wbmEUi2p-nA

http://blog.solutions-cubed.com/pid-motor-control-with-an-arduino/

http://forum.arduino.cc/index.php/topic,45169.0.html

http://playground.arduino.cc/Code/PIDLibrary

http://playground.arduino.cc/Code/PIDAutotuneLibrary

Arduino Playground: PinChangeInterrupt Library

https://code.google.com/p/arduino-pinchangeint/downloads/list

LetsMakeRobots: PID Control by Big Face

LetsMakeRobots: PID Tutorials for Line Following by Enigmerald

LetsMakeRobots: PID without a PHD by BDK6

LetsMakeRobots: Using Motor Encoders to Control Speed by Oddbot